A trusted supplier of high quality apparel with an excess value of 9M USD exported to more than 21 countries around the world.

Access to 10 vertically integrated factories equipped with the latest technology to deliver impeccable quality at scale.

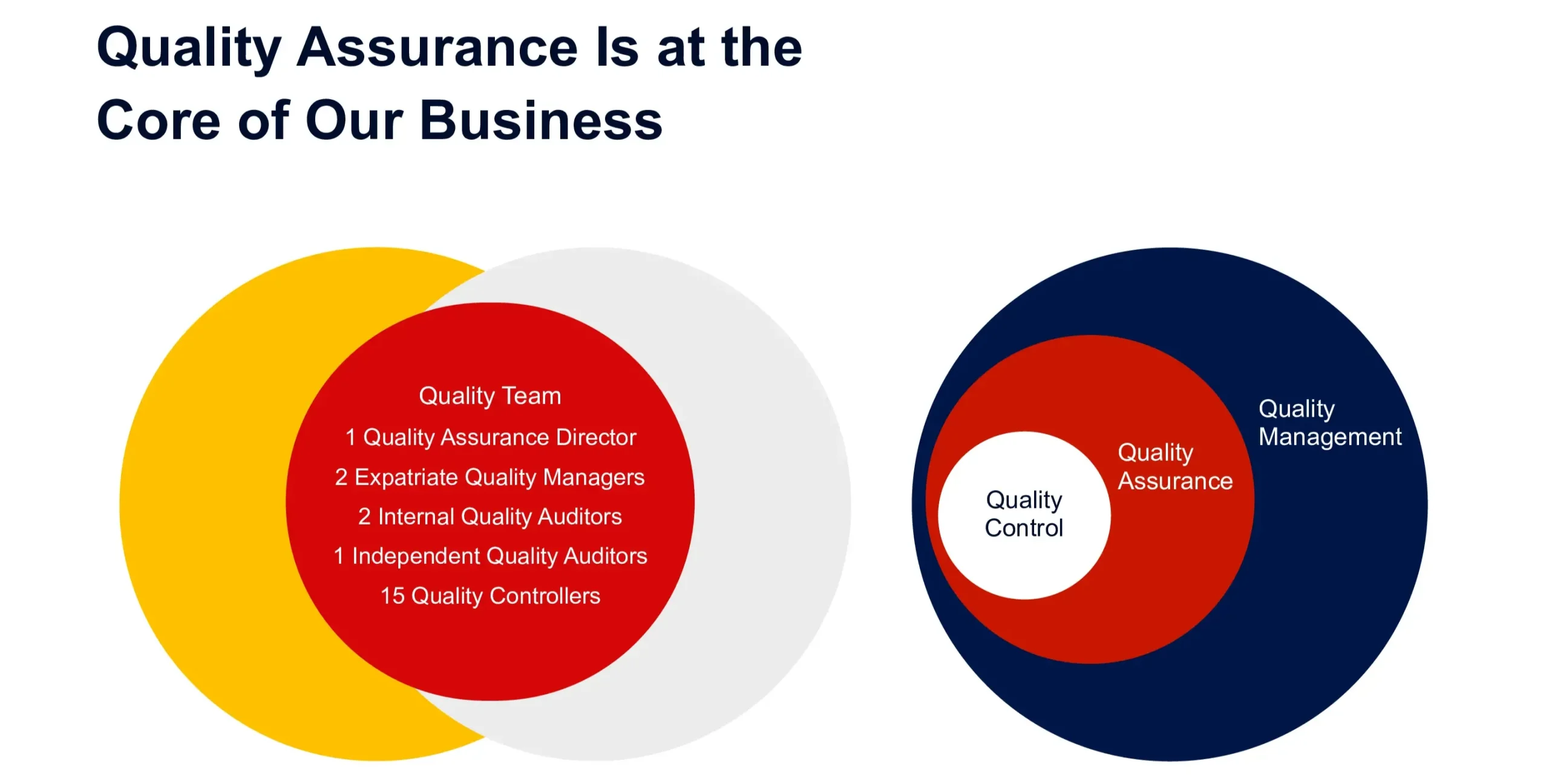

Our team’s collective experience, knowledge and ability help us produce quality and compliance products that meet your company objectives and goals.

Ecotex Global Limited is a complete one stop solution for textile buyers looking to procure effectively from Bangladesh. We understand the challenges involved and work in partnership with our clients to address the risks and deliver results to the bottom line.

Bangladesh

Corporate Headquarters

Uttara Business House

Sector 12, Uttara, Dhaka-1230, Bangladesh.

HP: +880 1671111137

Email: info@ecotexglobal.com

Web: www.ecotexglobal.com

United Kingdom

Sales & Marketing Office

71-75 Shelton Street, Covent Garden,

London, England, WC2H 9JQ.

Tel: +44 2030162403

WhatsApp: + 44 736 846 7723

Email: contact@ecotexglobal.co.uk

Web: www.ecotexglobal.com